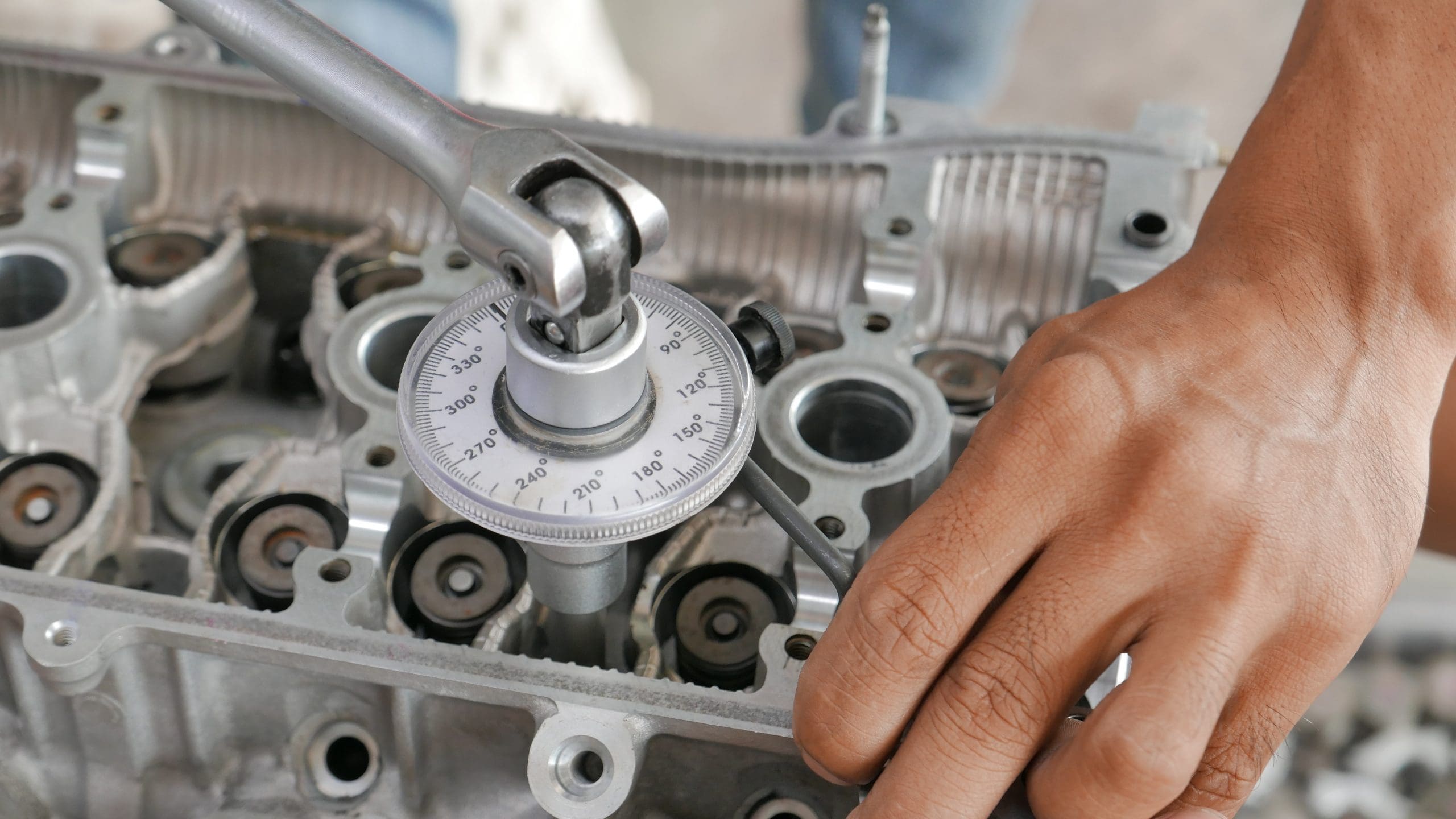

For the proud owners of torque wrench kits, it becomes essential to get proper torque wrench calibration done by a professional at regular intervals. Having the best and the most reliable tools in the arsenal is an important thing for the people belonging to the mechanical world. Certain tools might just do well without being given special care, while some others require special care and adjustment over a period of time.

Why is Torque Wrench Calibration Necessary?

Torque wrench calibration has a deep impact on the overall cost of ownership of the tool. Getting a torque wrench calibrated is essential in order to gets its accuracy verified. Apart from accuracy, calibration also measures the reliability of the jobs performed by the wrench from day-to-day working. The permissible window of calibration error is set at 5% and any error beyond that may seriously affect the performance of the tool.

How frequently should one calibrate the Torque Wrench?

Many who make regular use of torque wrenches or work with quality management at workshops often shoot a question regarding the frequency of torque wrench calibration. As a matter of fact, there is no one-size-fits-all practice that determines the intervals of torque wrench calibration. There are different kinds of wrenches that are needed for a wide variety of jobs and each one of them requires calibration after specific intervals to perform the job well.

Calendar based calibrations are a very popular fallback (for instance 6 months). However, it does not necessarily mean that calibrating every six months will help keep the torque wrench in perfect working condition. In the end, it all narrows down to how often and aggressive the tool has been used.

The frequency of torque wrench calibration mainly depends on the user and the frequency of usage. There aren’t any strict time periods or standards that must be followed for calibrating the torque wrench. Some professionals believe that the performance of the tool is affected between 2,500-3,000 repetitions. Therefore, it is generally recommended to calibrate the torque wrench after 2,500 repetitions have been made.

Key Points to Consider

- One must try to pinpoint any changes in the performance between 2500-3000 repetitions.

- Though calendar-based calibration isn’t the most professional practice, getting the wrench calibrated every six months could be considered the initial step in mending the tool.

- If the errors on torque reach beyond the permissible limit, recalibration needs to be considered.

- The owners should follow the thumb rule of “the more the usage, the more calibration needed.”

- If the torque wrench is subjected to overload equivalent to or surpasses 25% of the maximum limit, one should consider getting a recalibration done.

- Following general care tips in usage and storage will help maintain the ideal level of calibration for a longer period of time.

A torque wrench requires regular calibration, depending upon the frequency, degree, and kind of usage over a period of time. By learning about when to calibrate the torque wrenches, one would easily be able to correct the performance every time and attain reliable final results.

For more information on Torque Wrench Calibration, checkout: